The Degtyarev submachine gun model 1934 (PPD-34) is the first weapon of this type adopted by the Red Army. Its path from the creation of the first prototype to mass production dragged on for several years. The total number of PPD-34s produced is small, and, according to all estimates, is only about 5,000 pieces. Only a few copies of this rare weapon have survived to this day. It is all the more interesting to find documents about the various paths that the designer tried to take when developing his brainchild.

Thus, one of the PPD-34 variants involved the abandonment of the barrel casing, which resulted in a slight reduction in the weight of the structure. If this option had been approved, all submachine guns developed in the USSR later could have had a different appearance. The famous weapon of Victory - the Shpagin PPSh-41 submachine gun - would also most likely have had a different, less recognizable appearance.

In the fall of 1934, from September 9 to November 15, comparative tests of two variants of mass-produced submachine guns of the Degtyarev system were carried out at the Research Weapon and Machine Gun Test Site of the Red Army (NIOP) in Shchurovo, near Moscow. One of them had a light barrel casing, the other had a finned barrel without a casing.

The serial batch of PPD, manufactured in 1934, consisted of only 44 pieces. The submachine guns of this batch were intended for various tests, development of design and manufacturing technology. PPD No. 17 (with a casing) and PPD No. 28 (with a ribbed barrel) arrived at the test site.

PPD-34 with a barrel casing (from the collection of the Museum of Russian Military History in Padikovo, Istrinsky district of the Moscow region)

It was necessary to identify the accuracy of the battle, the practical rate of fire, the reliability and reliability of the weapon mechanisms. Upon successful completion of these stages of testing, it was intended to determine which of the barrel and casing options would be mass-produced in the future. Comparisons during testing were carried out with a sample tested at NIOP earlier, in 1932.

Significant changes have been made to the new samples. Thus, the receiver guide tray was welded (on earlier and later samples, it was apparently secured with pins). On the sighting bar, divisions were marked with the numbers 5, 10, 15, ..., 45, 50, which corresponded to firing distances of 50 m, 100 m, 150 m, ..., 450 m, 500 m. A latch was made on the rear stop screw, which eliminated the problem with the screw unscrewing itself.

For submachine gun No. 28 with a ribbed outer surface of the barrel and without a casing, the base of the front sight was put on the barrel. The weight of the submachine gun No. 17 in relation to earlier models was reduced by 65 grams, which was achieved mainly due to the lighter bolt by 40 grams. The weight of submachine gun No. 28 has been reduced by 110 grams.

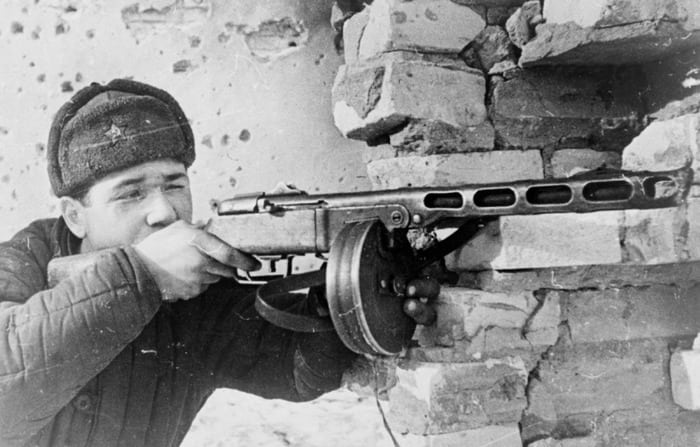

Degtyarev submachine gun with a ribbed barrel (RGVA)

Degtyarev submachine gun with a ribbed barrel (RGVA)

Shooting to determine the initial speed of submachine guns was carried out with 7.63x25 mm Mauser cartridges of foreign production manufactured in 1934. The average initial speed was 513 m/s, which was higher than previously tested (477 m/s).

The rate of fire was determined by the Tokarev device. The firing results showed that PPD No. 17 and No. 28 have a rate of fire equal to 900 rounds per minute, while in the summer of 1932 an experienced PPD showed a rate of fire of 800 rounds per minute. The increase in the rate of fire for the tested PPDs occurred due to a decrease in the weight of the bolt and an increase in the muzzle velocity.

An increase in the rate of fire led to a deterioration in the accuracy of combat during automatic fire, especially when shooting from a prone position, from the hand. To determine the accuracy of the battle, shooting was carried out at a distance of 100 meters: single fire, groups of 2–4 shots and continuous fire, three bursts for each type of shooting and 20 rounds in each burst. The firing results showed that the combat accuracy of the tested PPDs was somewhat better than the accuracy of previously tested samples.

The improvement in the accuracy of combat when firing from the test samples was attributed to the improvement in the quality of the cartridges (in 1932, the PPD was fired with domestically produced cartridges, which had a number of shortcomings), as well as to the qualities of the shooter, who had better mastered the shooting technique.

Head target No. 11, 1930s, USSR

Head target No. 11, 1930s, USSR

The determination of the practical rate of fire was carried out by targeted shooting at targets with single, group and continuous fire, taking into account all elements of shooting and changes in dispersion radii. Shooting was carried out at a distance of 100 meters from a shooting bench by shooters of various training levels.

A shooter with little training showed a rate of 18–19 rounds per minute with single fire, 25–26 in groups, and 65 continuous fire. A well-trained shooter was able to achieve a rate of 31 rounds per minute with single fire, 69 in groups, and 104 rounds per minute with continuous fire.

The small group training shooter showed an increase in the practical rate of fire by 1.4 times, while the accuracy deteriorated by 1.65 times. When firing with continuous fire, the practical rate of fire turned out to be 3.5 times higher, and the accuracy was 3.2 times worse. The comparison was made with a single fire. Under similar shooting conditions, in comparison with single fire, a well-trained shooter when shooting in groups showed a practical rate of fire 2.2 times higher, accuracy 1.4 times worse. When firing with continuous fire, the practical rate of fire increased by 3.4 times, and the accuracy was 2.2 times worse.

From this the conclusion was drawn: for a shooter with little training, fire in groups is less powerful compared to single fire; for a shooter with good training, fire in groups gives only a slight deterioration in accuracy compared to single fire, but the rate of fire increases significantly.

The following probabilities of hitting the head target at 100 meters were obtained (for a trained shooter):

- with a single fire P=0.75 (practical rate of fire 31 rounds per minute);

- when firing in groups P=0.60 (practical rate of fire 69 rounds per minute);

- with continuous fire P=0.33 (practical rate of fire 104 rounds per minute).

Neck of a PPD-34 magazine (from the collection of the Museum of Russian Military History in Padikovo, Istra district, Moscow region)

Neck of a PPD-34 magazine (from the collection of the Museum of Russian Military History in Padikovo, Istra district, Moscow region)

Firing to test the serviceability and reliability of the automation was carried out with a large number of shots - 5000 from PPD No. 17 and 1000 from PPD No. 28. The barrel was cooled with water after every 100 shots. In addition, after every 1000 shots, the gun was shot for accuracy from a distance of 100 meters in three bursts and the barrel was measured with calipers.

As a result, after testing PPD No. 17 after 5000 shots, the barrel remained almost unchanged, there were no parts broken. For the entire series of 5000 shots there were 90 delays, which is 1.8%.

A regular PPD-34 magazine (below) and modified at NIOP (above)

A regular PPD-34 magazine (below) and modified at NIOP (above)

The majority of the delays were attributed to poor fit of the magazine, which allowed for movement in the socket. To test this assumption, the design of one of the stores was modified and another 2000 rounds were fired. The version turned out to be correct: only two cases of distortion were recorded. After this, the conclusion was made: if we exclude delays caused by poor fit of the magazine, then for 5000 shots there will be a total of 44 delays, or 0.88%, which entirely depend on the design of the submachine gun itself.

PPD No. 28 had 15 delays per 1000 shots, or 1.5%. As a result, the conclusion was made: in terms of structural strength and operational reliability, the tested PPDs are satisfactory.

Magazine PPD-34 (from the collection of the Museum of Russian Military History in Padikovo, Istra district, Moscow region)

Magazine PPD-34 (from the collection of the Museum of Russian Military History in Padikovo, Istra district, Moscow region)

The PPDs were tested by fire to determine the reliability of the automation when dusty, at elevation angles of 80–90°, and with thick grease. The shooting results showed that when dusty and at angles of 80–90°, submachine guns work normally, but in the presence of thick lubrication they do not work at all due to the slow movement of the bolt forward, due to which the firing pin receives very little energy and misfires.

In the conclusions, it was noted that both with thick lubrication and with carbon deposits on the bolt, the speed of the latter when approaching the barrel stump quickly drops, and consequently, the energy of the firing pin decreases to an even greater extent, i.e. With this design of the impact mechanism, the automation is very sensitive to contamination.

With regard to the ease of use of the new SPD, no changes were noted in comparison with previously tested samples, but for convenience and the possibility of shooting while lying down in a SPD without a casing, it was necessary to make a small clip in front of the magazine from below, protecting the left hand from burns, because . on the butt in this area there was too little room for the fingers of the left hand, and therefore the thumb and forefinger rested on the barrel casing.

Serial PPD-34 produced in 1936, the fuse is visible (from the collection of the Museum of Russian Military History in Padikovo, Istrinsky district of the Moscow region)

Serial PPD-34 produced in 1936, the fuse is visible (from the collection of the Museum of Russian Military History in Padikovo, Istrinsky district of the Moscow region)

In addition, when handling the PPD, cases of random firing were possible when inserting a magazine with cartridges into the socket due to the fact that the bolt was not held in the closed position by anything. When a submachine gun with a magazine (not in a case) was behind the back, it was possible for the bolt handle to get caught on foreign objects and, accordingly, the bolt was cocked and fired. For example, a cavalryman, when mounting a horse, could hook the bolt handle behind a nearby rider or horse. To prevent such cases, it was necessary to provide a shutter delay that would hold the shutter in the closed state.

In conclusion, a point was indicated that determined the further type of submachine guns in the USSR:

“Of the two tested PPDs (with a casing and without a casing), NIOP Polygon considers it more appropriate to focus on the sample with a casing as it represents the greatest ease of use (carrying over the shoulders, better protects the shooter from accidental burns). Moreover, from a production point of view, the absence of a casing does not provide any particular advantages.”

The article was written based on documents from the Russian State Archive of State Archives

PPSh-41 is a Shpagin system submachine gun chambered for 7.62 mm, developed and adopted by the Red Army at the end of 1940. It was distinguished by high reliability and rate of fire. The simplicity of the design made it possible to produce it at non-core enterprises. This PP became the most popular automatic weapon during the Great Patriotic War (WWII) in the ranks of the armed forces of the USSR.

Captured PPSh were used in German units, converted. And it was sometimes called drum roll because of the very high volume of the shot.

Reasons and process of creation

Drawing conclusions from the Soviet-Finnish War (1939 - 1940), the leadership of the USSR gave the order to develop a modern and technologically advanced submachine gun (PP). The new weapon was supposed to match the combat characteristics of the PPD-34/40 (Degtyarev PP), but be easier to manufacture.

By the fall of 1940, G. Shpagin and B. Shpitalny presented their projects to the commission of the People's Commissariat of Armaments.

At the end of November, the Shpagin design bureau produced 25 products, the Shpitalny design bureau produced 15 units intended for testing tactical and technical characteristics. Along with the presented samples, PPD-40 also took part in the tests.

The tests included testing for structural strength, accuracy of fire, combat rate of fire and weight-dimensional characteristics.

By the end of the tests, the commission concluded that the Shpagin submachine gun was more suitable for the needs of the Soviet armed forces. Since it has better reliability, its parts are less susceptible to wear, with a mass equal to the PPD, it is easier to manufacture, and is not much inferior to the Shpitalny PP in accuracy and magazine capacity (but it weighs 1.5 kg more).

As a result, in December 1940, a decree was signed on the adoption of Shpagin's software and the start of its production. The project presented by Shpitalny was sent for revision, citing the low reliability of the automation.

Description and performance characteristics

The operating principle of the automatic Shpagin machine gun is based on a free-moving bolt and the use of recoil energy. The mainspring is cocked and activated when the trigger is pressed. Afterwards it straightens, which leads to the bolt moving forward and puncturing the cartridge case.

After the shot, the bolt, due to the powder gases, moves back to its original position.

The spent cartridge case flies out and a new charge takes its place. The ammunition is fed from a drum and sector type magazine. Hook type fuse. Around the barrel is a metal casing with oval holes and a bevel at the end. This innovation by Shpagin protected the fighter’s hands from burns and at the same time worked as a recoil compensator.

Looking at the large-scale cutaway plan of the PPSh submachine gun of the 1941 model, you can notice that the parts depicted on it are extremely simple and reliable.

Such design features allow it to be assembled on non-core production lines. For example, in tractor factories. The entire structure is made of steel, the butt is wooden (mostly birch). Parts are made by cold stamping and electric welding.

PP Shpagina has the following technical parameters:

- Weight: Without magazine – 3.6 kg. With a drum-type magazine - 5.3. With sector – 4.15 kg;

- Length: total product – 84.3 centimeters, barrel – 26.9 cm;

- Ammunition used: 7.62x25 mm TT, pistol;

- Caliber: 7.62 mm;

- Firing speed: up to 1000 rpm;

- Initial bullet speed: 500 m/s;

- Firing mode: automatic, semi-automatic;

- Firing distance max/effective: 500 m / 200 – 300 meters;

- Power type: drum (71 cartridges) and sector (35 cartridges);

- Sights: static, open type at 100 m and equipped with a folding line - 200 m.

Advantages and disadvantages

Like most types of weapons designed before and during the Great Patriotic War, the PPSh was extremely simple and effective. This weapon was appreciated not only by Soviet soldiers, but also by soldiers of the Allied countries and even in the Wehrmacht.

The Shpagin machine gun also had shortcomings, some of which were corrected already in 1942.

Briefly about the advantages

- Ease of production. The PPSh was assembled from spare parts made by cold stamping and spot welding. This did not require manual modification and saved time on machine hours. PPSh were even assembled by Belarusian partisans from parts made at home, without drawings;

- High rate of fire. The drum magazine was fired in ten seconds, which made it possible to create a high density of fire at a short distance, filling the enemy with hot lead. SMGs were mainly used in conditions of dagger combat: clearing trenches during tank landings, urban battles. In particular, for battles in urban areas, the PPSh-41 with a sector magazine was used, which increased the mobility of the serviceman.

Briefly about the disadvantages

- High weight and inconvenience. The simple design of the PPSh revealed a serious drawback - heavy weight. It weighed 5.3 kg with a drum magazine loaded. In addition, the fighter carried with him more ammunition and 2 spare clips. The problem was partly solved by introducing a smaller sector magazine. It had less mass and took up much less space;

- The drums of one PPSh did not fit the other. Cold stamping, although it produced a fast pace of product production, made each sample unique. In particular, this concerned cartridge power elements. If it was lost, it was extremely difficult to find a replacement, and given that only 3 magazines were produced with each barrel, this created a real problem;

- The high rate of fire led to quickly running out of ammunition. In fact, the fighter carried with him 3 equipped drums. A total of 223 rounds. With a rate of fire of 1000 rounds per minute, the ammunition was consumed very quickly. After which the soldier had to begin equipping the clip with new ammunition. In the conditions of current fire contact, this is very difficult. The problem of equipping the magazine with cartridges also aggravated the situation. It was difficult and if even one cartridge was misaligned, I had to start all over again.

- Some design flaws: a crossbow when dropped, the magazine falling out of the mount;

- Ease of manufacture did not mean high wear resistance of parts; this led to a loss of reliability of the machine. In battle conditions, this was an important factor. The battles took place in urban conditions, on rough terrain, in trenches. All these places were not clean. This claim mainly applies to non-core factories.

Why not PPD

The Soviet command never took the PP seriously. It was considered a weapon for the police and gendarmes. However, some Soviet designers proactively developed projects for their submachine guns.

One of these people was Degtyarev. Its PPD-34 was mass-produced and mainly served in the ranks of the NKVD border service.

After the Winter War with the Finns, who massively used Suomi PP. The leadership of the Red Army urgently instructed Degtyarev to finalize the PPD-34.

And in the winter of 1940, he presented a new modification of his project - PPD-40.

By the beginning of the Second World War, about 90 thousand copies of it were produced.

At the same time, Stalin ordered the involvement of the best gunsmiths in the creation of a new PP, which would be easier to produce, but retain the combat qualities of the PPD-40. He himself is complicated. To create it, you need high-precision equipment and manual grinding.

History of PPSh during World War II

The Shpagin submachine gun, also known as PPSh-41, became the most common automatic personal weapon of soldiers of the Red Army (Workers' and Peasants' Red Army).

It was distributed in various branches of the military: infantry, guards units, airborne groups. It was also actively used by partisans operating in German-occupied territory.

Even German soldiers willingly used it instead of the MP-38/40.

The ROA (Russian Liberation Army) of Vlasov also had their own PPSh.

Ease of use made it possible to reduce the training period for recruits. And this is important in conditions of military operations.

Taking advantage of the high rate of fire, they suppressed enemy soldiers with fire, which left them no chance to survive.

He performed well in urban battles. The Battle of Stalingrad can be called the baptism of fire for this weapon. The fierce battle for the city took place in densely built conditions and numerous confined spaces.

In this kind of battle, the main thing is the rate of fire and the ability to suppress the enemy with continuous fire. The same thing happened in Kharkov and in the spring of 1945 in Berlin.

Options and modifications

During its long existence, the PPSh was modified more than once, and a huge number of types of this machine gun spread throughout the world.

It is impossible to list all of them due to the wide distribution and uncontrolled movement of this software.

Officially, it was supplied to countries such as China, Vietnam, Poland and Cuba.

- PPSh-41 arr. 1941 - first sample. It was equipped only with a drum magazine and a sight designed for shooting at a distance of up to 500 m.

- PPSh-41 arr. 1942 – differs from the ’41 model by a chrome-plated bore (Increases wear resistance), more reliable fastening of the clip and the elimination of an involuntary shot when falling. It was equipped with an aiming device for shooting at 100 - 200 meters. A sector magazine made of steel 0.5 mm thick (Later – 1 mm);

- PPSh-2. In 1943, a competition was announced for the development of a new submachine gun, which was supposed to be a replacement for the PPSh. The main requirements were maintaining combat qualities, reducing weight and dimensions. The product presented by Shpagin, although it was further simplified in production, did not meet the requirements. The choice fell on the project of the gunsmith Sudakov.

Handicraft and semi-handicraft models:

- “Product No. 86” - were manufactured in Kandalaksha on the territory of plant number 310. Before receiving the drawings, 100 products were produced. All of them were made by hand and their parts were not interchangeable. Like production models, the machine gun was equipped with a drum magazine;

- Many samples of the Shpagin submachine gun were made in the workshops of various partisan detachments operating on the territory of Belarus;

- Jelen - Croatian semi-handicraft modification, which was actively used in the wars on the Balkan Peninsula.

In the ranks of the Third Reich:

- MP.41(r) – captured PPSh-41 converted to the 9x19 “Parabellum” pistol cartridge, common among the Germans. The weapon had a replacement barrel and a receiver for clips from the MP-38/40. In total, about 10,000 pieces were converted.

During the Second World War and after its end, PPSh was produced in many countries. Among them were China, Yugoslavia, Iran, Croatia, Vietnam, Hungary, North Korea, etc.

Basically it was an ordinary Shpagin submachine gun. Only in rare cases were minor modifications made to suit the realities of local industrial potential.

Conversion options

- PPS-50 – Manufactured by Pletta. Uses small caliber ammunition - .22 LR;

- SR-41 Semi-Auto Rifle – Produced by the American arms company “Inter-Ordnance of America”. There is a modification chambered for 7.62x25 and 9x19 mm. Has an increased barrel length. American weapons connoisseurs have always spoken highly of the PPSh-41.

- SKL-41 – developed for the 9x19 cartridge. Start of production 2003

- PPSH 41 SemiAuto is a self-loading modification using a 7.62x25 cartridge. The key feature is an extended barrel (up to 16 inches), a casing without specific and recognizable oval holes. Shooting occurs with the shutter closed. Manufactured by the American company “Allied Armament”;

- VPO-135 – Cartridge 7.62x25. System: self-loading carbine. Date of development: 2013. Produced by the Molot plant;

- PPSh-O – Cartridge 7.62x25. System: self-loading carbine. Date of development: 2013. Produced by the Kovrov plant named after Degtyarev;

- MR-562K “PPSh” is a pneumatic version developed at the Izhevsk plant. Shoots 4.5 mm metal balls. Can fire in bursts.

Myths and legends about PPSh

Around each weapon there is a huge number of myths associated with it or the people who created it. The Shpagin assault rifle is no exception.

Here is just a small part of these legends:

- PPSh is a copy of the Finnish Suomi assault rifle. This is wrong. Although there is an external resemblance, it is only external. The internal mechanism is different;

- There is a shortage of automatic weapons among Soviet soldiers and, on the contrary, a large number of such weapons among the Germans. The same myth “one rifle for five soldiers.” The Germans often used captured SMGs, precisely because of their lack of weapons of this class;

- PPSh-41 is the best submachine gun of the Great Patriotic War. The truth is that he was like this before graduation;

- The last country to remove the PPSh-41 from service is Belarus. This happened in 2003.

Submachine gun PPD-40 (USSR)

![]()

PPD-40 submachine gun Photo (c) Jakes

On February 15, 1940, Degtyarev presented a modernized version of his submachine gun, designed with the participation of designers from the Kovrov plant P.E. Ivanova, S.N. Kalygina, E.K. Alexandrovich, N.N. Lopukhovsky and V.A. Vvedensky. The new weapon had a split stock made of two parts, located before and after the store. These parts were equipped with metal guide stops intended for mounting the magazine, which made it possible to use a drum magazine without a protruding neck. The capacity of such a magazine was reduced to 71 rounds. However, the reliability of cartridge supply has increased significantly. The use of sector box magazines, also called “horns”, in the new submachine gun became impossible in the 1934 model submachine gun. They returned to box-shaped “horns” only during the Second World War, thanks to the combat experience of using the PPSh-41 among the troops, which showed the excessive capacity of the drum magazine and its too large mass. A new version of the Degtyarev submachine gun was approved by the Defense Committee under the Council of People's Commissars for production on February 21, 1940 and put into service as the “submachine gun of the 1940 model of the Degtyarev system” - PPD-40. Production of PPD-40 began in March of the same year.

A total of 81,118 PPD-40 submachine guns were produced throughout 1940. As a result, the 1940 model is the most widespread in terms of the number of copies produced. In addition, the armed forces received a fairly significant amount of countermeasures. The PPD-40 submachine gun was used at the very beginning of the war, but this type of weapon was still greatly lacking in the troops, and compared to the enemy, the Red Army was significantly inferior to the Wehrmacht in the number of available submachine guns. Already at the end of 1941, the PPD-40 was replaced by the much more technologically advanced and cheaper to produce, more reliable Shpagin PPSh-41 submachine gun, designed in 1940. A huge advantage of the PPSh-41 was that this weapon was originally developed taking into account mass production at any industrial enterprise with low-power pressing equipment. This circumstance turned out to be extremely important during the war.

But at first, while the production of PPSh-41 had not yet reached the required scale, in the initial period of the war the production of PPD-40 was temporarily restored at the Sestroretsk Tool Plant named after S.P. Voskov in Leningrad. Since December 1941, PPD-40 began to be manufactured at the plant named after. A.A. Kulakova. At the Kovrov plant, about 5,000 PPD-40 submachine guns were assembled from available parts. In total, for 1941-1942. In Leningrad, 42,870 PPD-40s were produced, which entered service with the troops of the Leningrad and Karelian fronts. Many Leningrad-made PPD-40s, instead of a sector sight, were equipped with a simplified folding sight, as well as a simplified fuse configuration. Later, using the same production facilities, the production of a much more technologically advanced Sudaev submachine gun was carried out. The PPD-40 fire was considered effective up to 300 m when firing single shots, up to 200 m when firing in short bursts, and up to 100 m in a continuous burst. The destructive power of the bullet was maintained at distances of up to 800 m. The main type of fire was short burst fire. At distances less than 100 m, continuous fire was allowed at a critical moment, but in order to avoid overheating of no more than 4 magazines in a row.

Specifications

Caliber: 7.62×25

Weapon length: 788 mm

Barrel length: 267 mm

Weight without cartridges: 3.6 kg.

Rate of fire: 800 rounds/min

Magazine capacity: 71 rounds

![]()

Submachine guns

- Austria

Don’t be confused by the “PPD machine gun” - this is a fairly common “folk” name for the Degtyarev submachine gun. Experts do not accept it (and rightly so), but it has taken root among the people and is very often used in search queries.

I won’t use it anymore, but you must understand that when I talk about the PPD submachine gun, I’m also talking about the PPD assault rifle (sorry about the oil).

Before moving directly to the PPD, I would like to offer you a brief excursion into the history of the creation of automatic weapons in Russia, and subsequently in the USSR. The fact is that the PPD became the first serial submachine gun adopted by the Workers' and Peasants' Red Army (that is what the Soviet Army was called until 1946). This weapon is criticized quite a lot and actively, for this reason I would like to talk about the reasons for the adoption of the PPD by the army, and remove a number of far-fetched accusations from a quite decent (in my opinion) submachine gun.

History of the creation of PPD

I will not remember the automatic and semi-automatic rifles developed in the pre-Soviet period, since these are slightly different small arms. Here you need to understand that the main distinguishing feature of a submachine gun is the use of a pistol (revolving) cartridge or a cartridge similar in its performance characteristics to a pistol.

The length of the barrel and the principles of operation of the automation (as a rule, this is the use of blowback recoil) are important characteristics, but, nevertheless, secondary.

Based on the principle we have adopted, the first truly Soviet submachine gun can be called a submachine gun, created in 1927 by Tokarev.

Tokarev submachine gun 1927

This PPT had quite decent characteristics for its time, and passed competitive tests well with the Volmer submachine gun, which was developed in Germany. However, there was no real and complete success for the simple reason that Tokarev developed his submachine gun for the Nagan revolver cartridge (the shape of the cartridge case was changed for better chambering). The cartridge, frankly, is not at all suitable for automatic weapons.

In 1929, designer V.A. Degtyarev offered the state commission his submachine gun, which was designed on the basis of a previously created light machine gun by the same designer. The Degtyarev submachine gun of 1929 had the same semi-free bolt as the machine gun with lugs extending to the sides, and the receiver design was similar. Accordingly, the “machine-gun” disk magazine for 22 rounds of the Mauser system has also been preserved.

Degtyarev submachine gun 1929

It must be said that since the early thirties, designers in the USSR developed their submachine guns exclusively for the Mauser pistol cartridge. This is due to the fact that the TT pistol (Tula-Tokarev) was adopted by the army; accordingly, mass production of cartridges for this pistol was established. In case you don’t know, the TT cartridge, before becoming the TT cartridge, was called the Mauser cartridge.

So, it was for this cartridge that the designers Korovin, Shpitalny, Degterev, Prilutsky and Kolesnikov developed their submachine guns.

Degtyarev submachine gun model 1934

In 1935, the Degtyarev submachine gun model of 1934 was adopted by the Red Army.

What can you say about PPD-34? A submachine gun with a blowback bolt, a sector magazine for 25 rounds, with a round receiver, which in the front part turned into a casing with ventilation cutouts, and in the rear part the receiver was closed with a screw cap. The fire switch flag was located in front of the trigger. The safety is located directly on the charging handle and allows you to lock the bolt in the forward and rear positions.

The submachine gun was equipped with a sector sight for firing at a range of 500 meters.

Many authors talk about a large number of fatal shortcomings of the PPD-34, which became the reason for the removal of this submachine gun from army service. It must be said that such statements are based more on guesswork than on real and objective facts. Yes, the PPD-34 had a number of technical shortcomings that were not typical of a conventional rifle. But that’s why it’s automatic, i.e. a more complex mechanism that requires constant fine-tuning and modernization even in production samples.

And such work was carried out. Soon, as a result of the modernization of the PPD-34, the PPD-34/38 submachine gun appeared.

Degtyarev submachine gun - 34/38

In my opinion, the main reason for the lukewarm reception of the new submachine gun in the army was not the technical shortcomings of the weapon (they actually existed), but rather political reasons. The military leadership wanted to obtain a weapon that could conduct effective automatic fire at rifle distances (at least 500 meters). Those. it was supposed to simply replace the rifle with a kind of machine gun that every soldier would be armed with.

The emergence of new automatic weapons with “different” characteristics required the development of appropriate tactics for their use. Those. it was necessary to reconsider the ideas about the conduct of combat by ground forces that had been established since the Civil War.

And this is after mass repressions in the army and navy, accusations of espionage and anti-state activities. At that time, it took great personal courage to turn to the military-political leadership of the country with such proposals. Moreover, by that time the general line of the party had already been firmly established, which assumed that the submachine gun would be only an “auxiliary weapon” for the regular army.

The Winter War with Finland put everything into place. Small detachments of Finnish skiers, armed with Suomi submachine guns, infiltrated the front line of Soviet troops and launched sabotage raids on individual units. This is where submachine guns showed their high efficiency - sudden, high-density dagger fire from short distances.

As a result, “by popular demand,” submachine guns were not only returned to the army, but they were actually mass produced. And very soon Degtyarev proposed an improved model of his submachine gun - PPD-40.

Degtyarev submachine gun - 40

All the talk about the high cost of producing PPD is talk “in favor of the poor.” The production of one PPD machine gun cost 900 rubles. Some authors claim that it was very expensive. And the production of one Tokarev automatic rifle, which was adopted as the main weapon, cost 880 rubles. Is 20 rubles incredibly expensive? I do not think so.